Release Performance in Your Storehouse Procedures With a High-grade Stretch Covering Equipment

Efficiency in storehouse procedures pivots on the effectiveness of the packaging process. The intro of a high-grade stretch covering device can be a game-changer, appealing performance, reduced labor costs, and reduced human error. With the capability to manage various load sizes and wrap many pallets per hour, these machines provide a compelling proposal for any kind of organization aiming to maximize its operations. What makes these machines such an essential property in warehousing? Allow's check out additionally.

Recognizing the Role of Stretch Covering Machines in Storage Facility Procedures

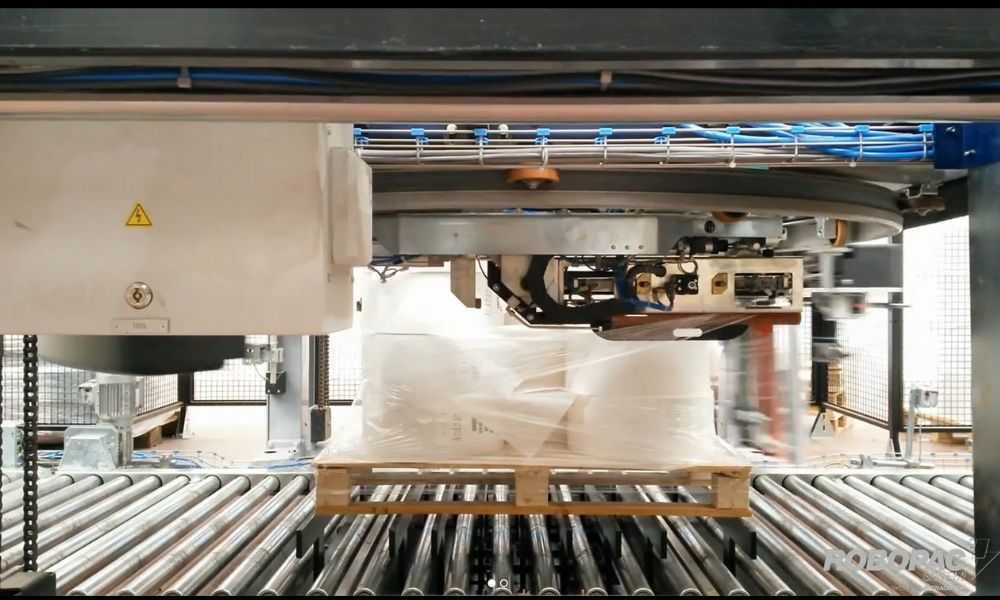

In the huge realm of storehouse operations, the relevance of stretch wrapping makers can not be overstated. They offer a vital duty in making certain that products are securely and securely packed for storage or transportation. These devices use an extremely stretchable plastic movie around items, securely wrapping them together in a manner that hands-on wrapping simply can not match.

Stretch wrapping makers can manage large quantities of products swiftly, significantly speeding up the packing procedure. The consistent covering given by these equipments can decrease the danger of tampering or theft during transportation.

Key Features of High-Quality Stretch Covering Machines

While there is a vast array of stretch covering devices readily available in the marketplace, high-grade designs share particular crucial features that set them apart. These machines are commonly robust, designed to stand up to considerable use without compromising on efficiency. They provide a high level of automation, enabling for reliable and problem-free covering of products.

Premium stretch wrapping equipments likewise include flexible settings, giving versatility to suit numerous product packaging demands. They can manage different dimensions and kinds of tons, ensuring a safe cover every time. These devices are additionally renowned for their rate, with the ability of wrapping various pallets per hour, therefore significantly increasing efficiency.

An additional key function is their integrity and reduced maintenance demand. Top notch machines are developed to last, minimizing the regularity of break downs and the linked downtime. They run with precision, making certain consistent cover tension, thus lowering waste and enhancing the presentation of wrapped products.

The Influence of Stretch Covering Makers on Storehouse Effectiveness

The efficiency of a warehouse can be significantly boosted with making use of premium stretch wrapping machines - stretch wrapping machine. These makers improve the packaging procedure, minimizing the hands-on labor involved and as a result, the chance for human mistake. This makes certain a much more constant and dependable wrapping process, leading to enhanced safety of items during transportation

In addition, stretch wrapping equipments can deal with a greater volume of items in a shorter quantity of time contrasted to hands-on covering. This heightened efficiency can result in much better application of storehouse room as goods can be packaged and relocated much more swiftly. The machines likewise offer the versatility to suit different dimensions and forms of products, further improving functional efficiency.

Computing the Return on Financial Investment for a Stretch Covering Device

Considering the substantial benefits of stretch wrapping machines, it's crucial to recognize the monetary implications of spending in such devices. The return on investment (ROI) calculation is a straightforward yet reliable tool to analyze the productivity of this investment. The ROI is calculated by contrasting the expense of the device with the financial savings created over a certain period.

The greater the ROI, the a lot more successful the financial investment. look at this web-site However, this number should not be the sole determinant in the decision-making process. Companies ought to likewise think about elements such as tactical positioning, operational efficiency, and scalability. In verdict, computing the ROI gives a clear economic point of view to assist the financial investment decision in stretch wrapping machines.

Real-world Situation Studies: Success Stories of Applying Stretch Covering Machines

Drawing from the economic ramifications talked about in the previous section, it is just as enlightening to analyze practical applications and success tales of business that have applied stretch covering devices in their procedures. One such instance is a multinational electronic devices business which reported a 30% reduction in harmed items during transit after introducing stretch wrapping makers in their packaging process.

Another success tale entails a leading food and beverage business. After implementing a stretch covering device, they saw a considerable renovation in their packaging rate, which subsequently increased daily outputs and overall performance.

Finally, a distinguished furnishings producer had the ability to cut down their product packaging product costs by an astonishing 40% after changing to extend covering devices; they simultaneously decreased their carbon impact, making their procedures much more lasting. These real-world study demonstrate the remarkable returns and efficiency gains that stretch covering equipments can bring to storage facility procedures.

Verdict

To conclude, investing in a high-grade stretch wrapping device can substantially boost warehouse operations. With its capability to decrease manual work, lessen mistakes, and boost room usage, it significantly improves performance and productivity. The ROI, coupled with success stories from real-world implementations, further underscores the vital function of stretch wrapping makers in accomplishing functional effectiveness and company success.

The introduction of a top notch stretch covering maker can be a game-changer, appealing check my blog effectiveness, decreased labor costs, and minimized human error.In the vast world of stockroom procedures, the relevance of stretch wrapping devices can not be overstated.The efficiency of a warehouse can be significantly boosted with the usage of top notch stretch wrapping devices.Moreover, stretch covering makers can deal with a higher quantity of products in a shorter quantity of time compared to manual covering.In final thought, investing in a high-quality stretch covering device can significantly boost storehouse operations.

Comments on “Key features to look for in a stretch wrapping machine”